Industrial machinery for the manufacture of specialized parts

Efficient, precise, and large-scale manufacturing solutions

CNC Production

We have high production capacity in both CNC lathes and machining centers. We offer precision and excellent quality finishes, ideal for demanding industrial processes. We adapt to your needs with monthly, quarterly, or annual contracts, and provide deliveries throughout Mexico and the United States.

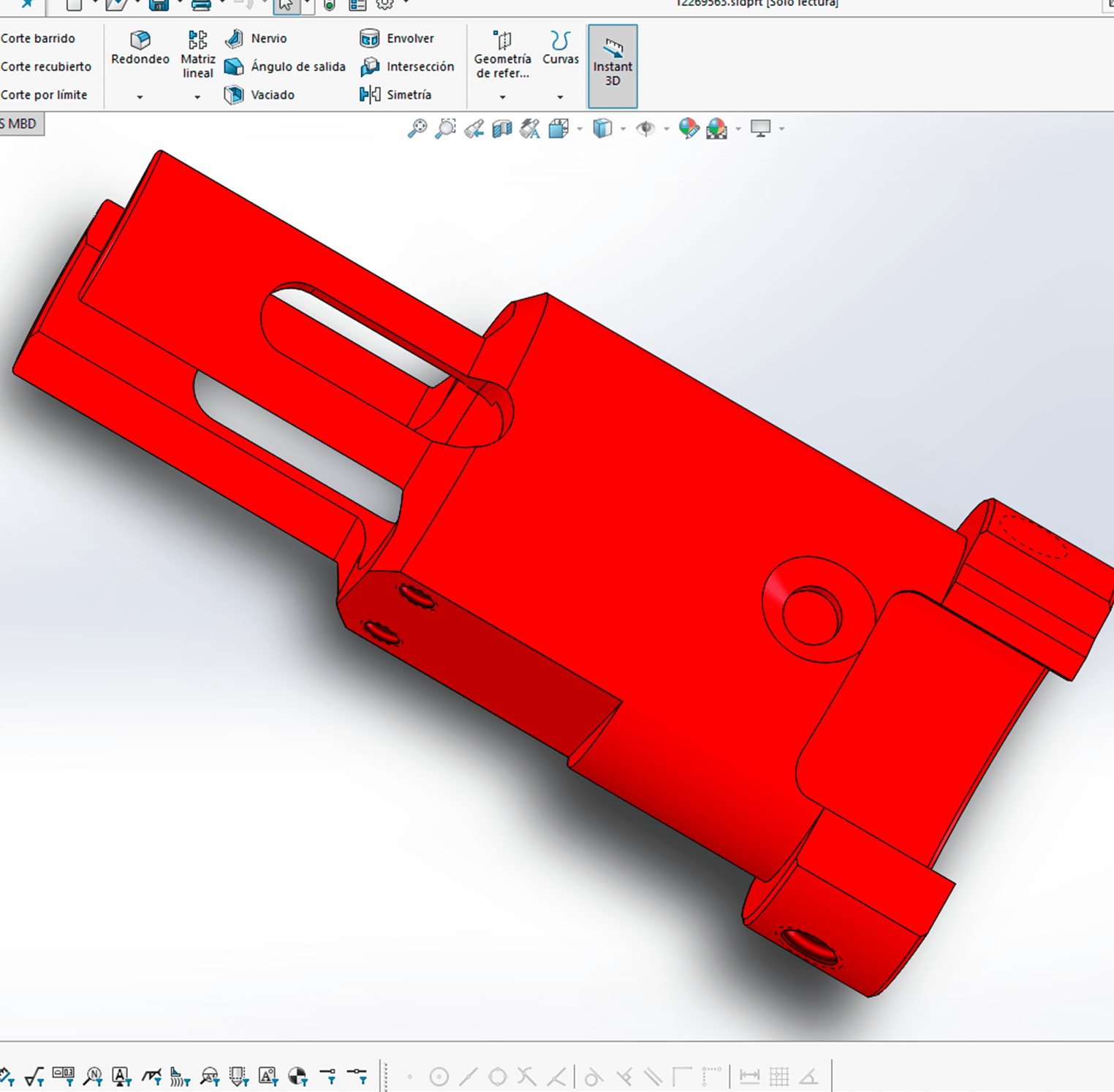

We work with tolerances of up to 0.00007 in (0.002 mm), depending on the design and complexity of the part. We specialize in the manufacturing of components such as gauges, core pins, molds, punches, and dies, ensuring precision and reliability in every detail.

We design and manufacture complete die sets, fully assembled and tested, ready for operation. In addition to punches and dies, our parts are made using high-precision Wire EDM machinery and finished on grinders to achieve the ideal edge.

We manufacture parts based on designs provided by our clients, fully respecting their technical specifications. This service is ideal for custom developments and specific production needs.

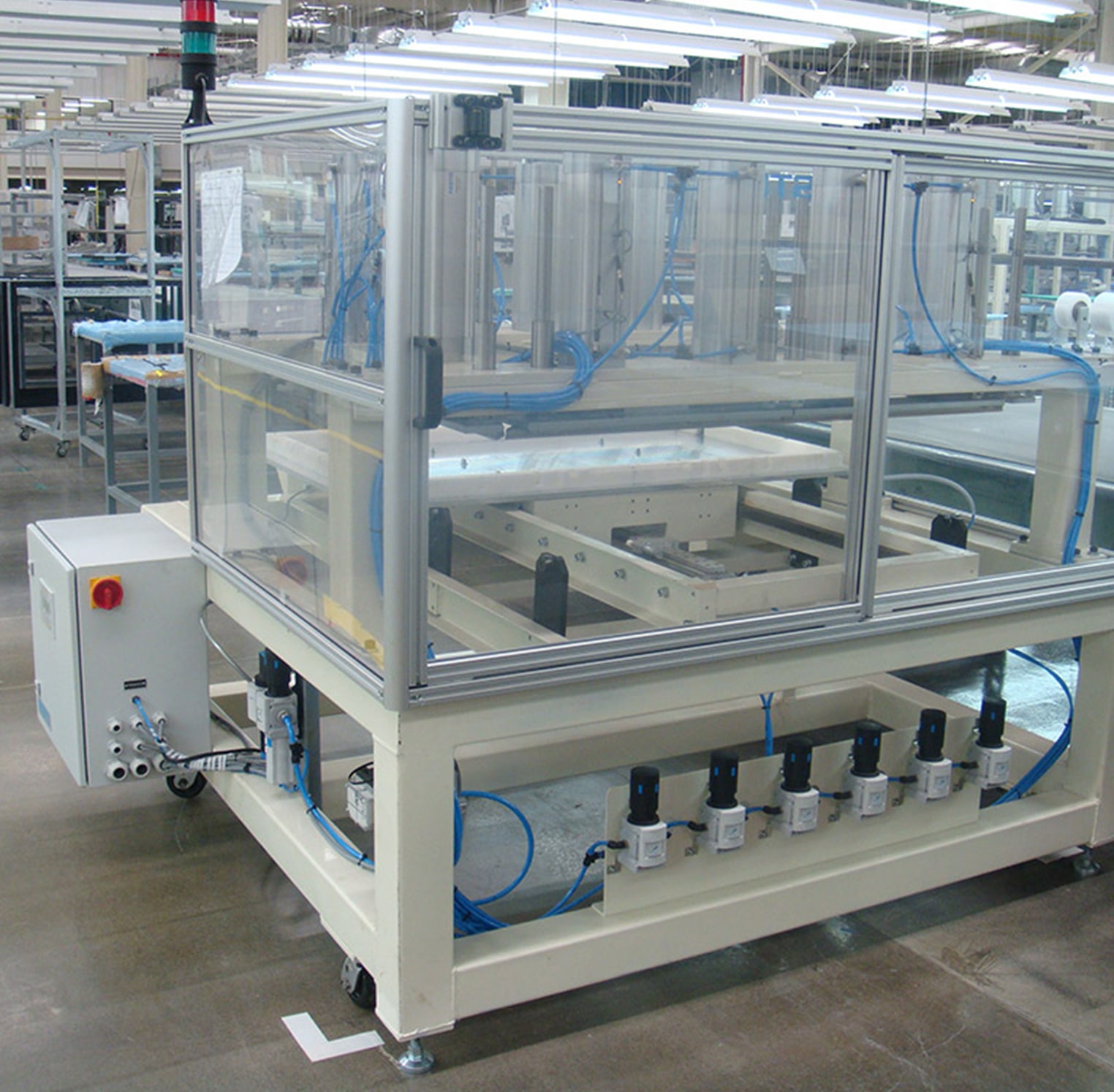

We design and manufacture fixtures that optimize assembly processes in production lines. Our design team develops functional prototypes, which, once approved, are machined and assembled with precision for immediate implementation.

We have a specialized welding workshop for manufacturing metal structures, tables, cabinets, industrial furniture, and more. We work with arc, TIG, and MIG welding, and materials such as aluminum, stainless steel, silver, carbon steel, carbide, and copper.

With calibrated and certified instruments, we offer dimensional inspection services and design consulting. Our team is proficient in platforms like SolidWorks and AutoCAD, and we are currently in the process of integrating CATIA to expand our engineering capabilities.

We offer a wide range of chemical and thermal treatments to maximize the performance and durability of your parts:

We perform high-precision laser engraving without physical contact or the use of inks, preventing wear from friction. Our technology allows for chemical and physical alterations on the surface, such as color changes, carbonization, foaming, and ablation, making it ideal for durable industrial identification.